Description

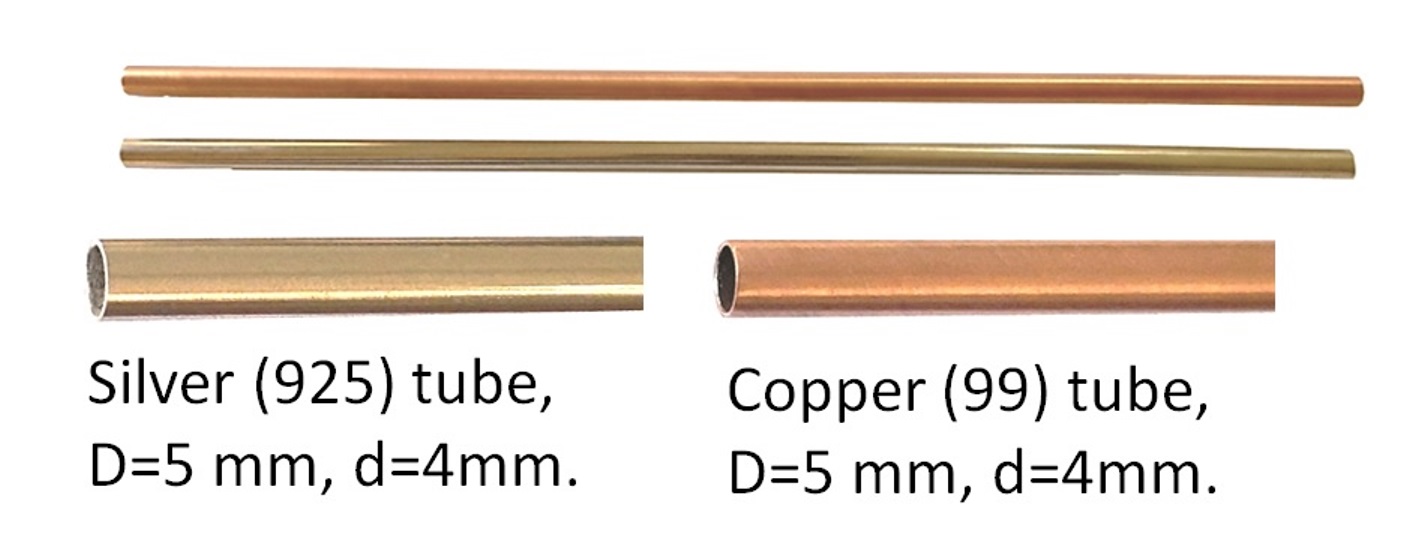

Place silver or copper tube in glass bead hole, flare and flatten both ends to form an excellent finish.

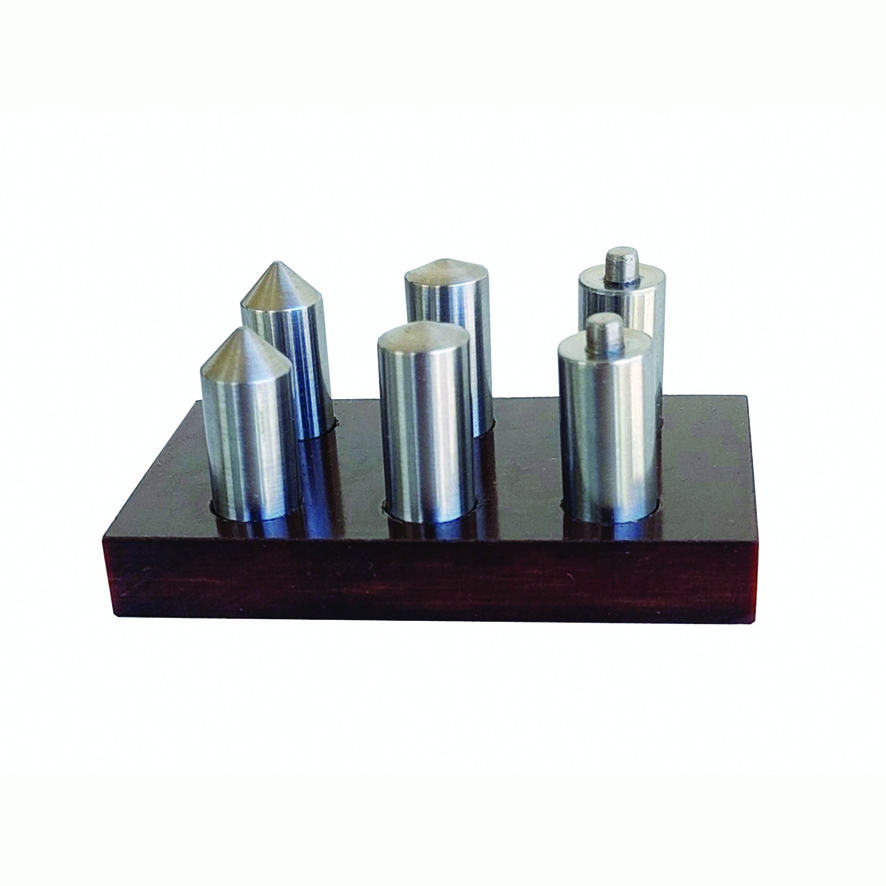

This tool is manufactured precisely from Aluminium and Steel, strong and robust construction for flaring tube ends.

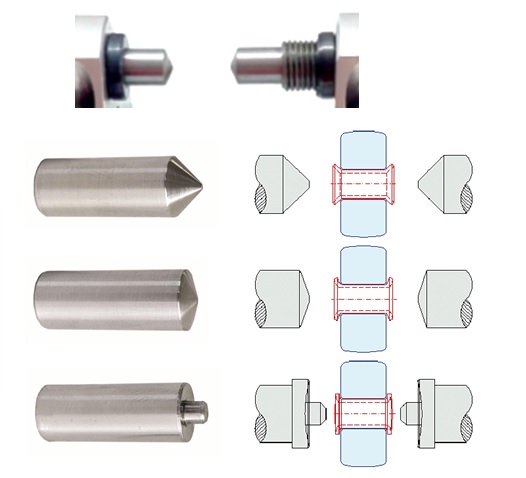

There are 3-different heads to form the desired ends.

Tool is designed to work at horizontal position, to control and observe the operation.

Fix the tool to a surface by screws or double sided tapes. You don’t have to keep the tool with hands during operation.

You can view movements, and control flaring tube and flattening process precisely.

It will take less than a minute to finish complete lining.

Operation:

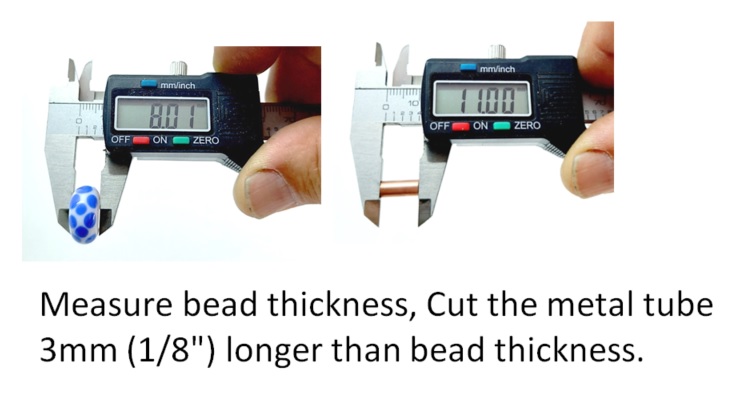

1-Measure thickness of the bead.

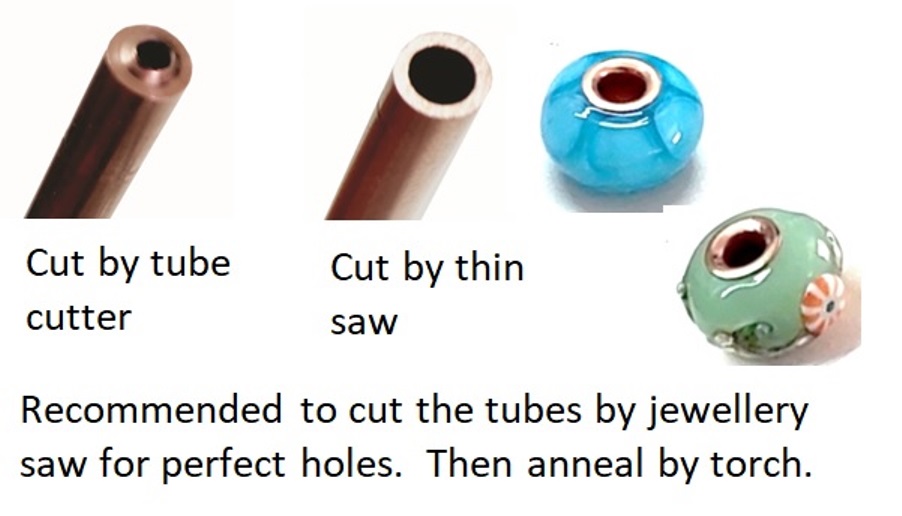

2-Cut the metal tube 3.0-3.5 mm (1/8″) longer than bead thickness.

3-Anneal metal tube by heating with a torch, then leave for cooling, this will soften metal.

4-Remove sharp edge and deburr holes by a countersink drill.

5-Place the tube in the hole of the bead.

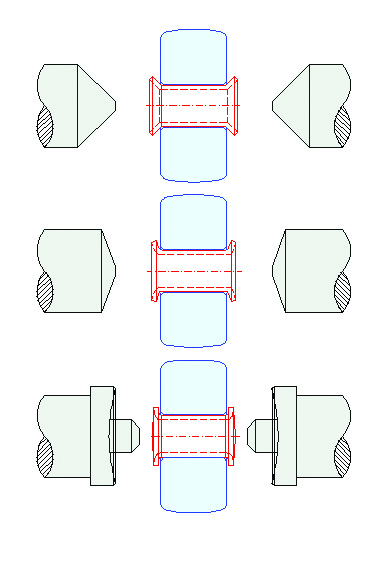

6-Place narrow angle inserts in the holes.

7-Place the bead with tube inside, between the inserts, position the bead equal distance from left and right.

8-Start turning the knob until inserts will expand and flare the tube.

9-Place the wide angle inserts and repeat same operation.

10-Place the concave curved inserts and pres untill tube will flare completely and cover the surface.

11-Polish the surface for excellent lining.